Message from the Executive Committee

A blooming carinata field in the spring time is a sight to behold, and if you have not seen one yet, go visit a carinata research plot near you. This tiny mustard has immense potential to deliver what’s demanded of it in the renewables space. And what’s demanded in this space is not insignificant.

At the 2nd SPARC annual meeting held in conjunction with the 6th Carinata Biomaterials Summit in Quincy, FL, we were able to reflect on some of these demands that our industry partners encounter in the path to product commercialization. These demands impose constraints and “…we like constraints… we are here to overcome constraints…” said Dr. Mike Mulvaney as he echoed several of our team member’s response to the need to work within established standards of sustainability for a product to be viable in the marketplace.

Another energizing gathering that we had the opportunity to be at was the Advanced Bioeconomy Leadership Conference (ABLC) at Washington DC. This is where all the who’s who in the renewable energy arena get together to share ideas, celebrate each other’s successes and brainstorm the challenges that this community collectively faces.

Another meeting we participated in was the National Sustainability Summit (NSS) and the National Extension Energy Summit (NEES). Despite the marked difference in the nature of both the ABLC and the NSS-NEES, the common theme in both the meetings was carbon. Take C out of the atmosphere and put it back in the soil. That was a heartening message coming from industry, academia, and government alike. “…think science in the boardroom and, markets in the lab…” is one of the takeaways we got from the ABLC that’s most relevant for SPARC as we continue on our mission to commercialize Carinata in the Southeast. We need that mindset to succeed and, we think we have it!

SPARC Stories

SPARC Research Looks Beyond Fuels from Carinata

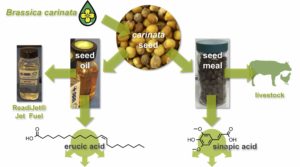

There are two reasons that SPARC is not named SPAFC. The first reason is that SPAFC sounds silly. The second reason is that this Southeast Partnership is focused on Advanced Renewables, not just Advanced Fuels from Carinata. To be sure, the Carinata biomill promises to yield primarily fuels for combustion, but this tiny mustard seed from Ethiopia has much more to offer.

Preliminary cost  analysis of ReadiJetTM fuel from Carinata suggests that it is cheaper than petroleum-based fuel when the price of crude oil exceeds about $100/barrel. This was true most of 2012–2014, but has not been the case since. In order to improve the overall economics, value added byproducts from Carinata have been explored and can be considered in two groups: seed meal as food for livestock and biobased chemicals. The latter is especially important given various national objectives to increase the bio-sourcing of chemical building blocks. For example, the USDA BioPreferred® Program (https://www.biopreferred.gov), created according to the 2002 Farm Bill and expanded as part of the Agricultural Act of 2014, targets the “increased development, purchase, and use of biobased products, reduces our nation’s reliance on petroleum, increases the use of renewable agricultural resources, and contributes to reducing adverse environmental and health impacts.” The BioPreferred® Catalog currently lists over 20,000 biobased products in 109 separate categories. Presently about 10% of our chemical intermediates are biobased and a goal of 20% is targeted by 2025, corresponding to an annual 12% increase (USDA, U.S. Biobased Products Market Potential and Projections through 2025).

analysis of ReadiJetTM fuel from Carinata suggests that it is cheaper than petroleum-based fuel when the price of crude oil exceeds about $100/barrel. This was true most of 2012–2014, but has not been the case since. In order to improve the overall economics, value added byproducts from Carinata have been explored and can be considered in two groups: seed meal as food for livestock and biobased chemicals. The latter is especially important given various national objectives to increase the bio-sourcing of chemical building blocks. For example, the USDA BioPreferred® Program (https://www.biopreferred.gov), created according to the 2002 Farm Bill and expanded as part of the Agricultural Act of 2014, targets the “increased development, purchase, and use of biobased products, reduces our nation’s reliance on petroleum, increases the use of renewable agricultural resources, and contributes to reducing adverse environmental and health impacts.” The BioPreferred® Catalog currently lists over 20,000 biobased products in 109 separate categories. Presently about 10% of our chemical intermediates are biobased and a goal of 20% is targeted by 2025, corresponding to an annual 12% increase (USDA, U.S. Biobased Products Market Potential and Projections through 2025).

Biobased Chemicals from Carinata Seed Oil: The fatty acid distribution profile for Carinata seed oil shows the most abundant component is erucic acid at 42% (ARA analysis). Erucic acid is a 22-carbon mono-unsaturated fatty acid (-9, 13 with formula CH3(CH2)7C=C(CH2)11COOH) too long for human digestion, but ideal for refining into Jet A fuel, which has a hydrocarbon distribution in the range of 8 to 16 carbons. Combined, oleic acid, linoleic acid, and linolenic acid make up 29% of the fatty acids. These are 18-carbon mono-, di-, and tri-unsaturated fatty acids (all 9), respectively. These four fatty acids are now targeted for various applications. Perhaps the most obvious is their conversion to monomers for polymerization. For example, erucic acid oxidation readily yields a 13-carbon di-acid called brassylic acid, which is essentially impossible to synthesize from fossil fuels in meaningful amounts.

In 1977, brassylic acid was converted to a 13-carbon di-amine, which was copolymerized with brassylic acid itself to yield the polyamide, nylon 13,13. This polymer exhibits thermal properties (Tm = 183 °C) nearly identical to that of nylon 11 (Tm = 190 °C), an industrial product long made by Arkema (Rilsan™) from the ricinoleic fatty acid of castor seed oil.

One current use of brassylic acid is a cyclic di-ester made from it and ethylene glycol; this ethylene brassylate is a high-value, small-production perfume ingredient with “musk, powdery, sweet, floral, woody, spicy, and vanilla nuances.” The byproduct of erucic acid oxidation is a 9-carbon acid, pelargonic acid (nonanoic acid), which is present in many food plants. While it is approved by the U.S. Food and Drug Administration for use in food, it also is gaining popularity as a green herbicide, fungicide, and sanitizer. The unusual length of erucic acid suggests an additional application in biobased, synthetic waxes. For example, behenic acid, made by hydrogenating erucic acid, can be esterified with pelargonic alcohol (nonyl alcohol), available from pelargonic acid. This yields a 31-carbon linear mono-ester (pelargonyl behenate) that is structurally similar to components of lanolin wax (from sheep wool). This provides a plant-based, vegan lanolin wax substitute that probably exhibits the same skin protectant properties without the allergies sometimes associated with animal-derived waxes. Behenic acid has other current applications, mostly for hair/skin care or lubricating oils. The corresponding amides, erucamide and behenamide, are increasingly used as polymer or coating additives. Oxidation of the aforementioned 18-carbon unsaturated fatty acids (oleic, linoleic, linolenic acids) yields a single 9-carbon di-acid called azelaic acid. This di-acid has the same potential use for making various nylons, but is mostly used in skin conditioners/medications (e.g., Finacea™).

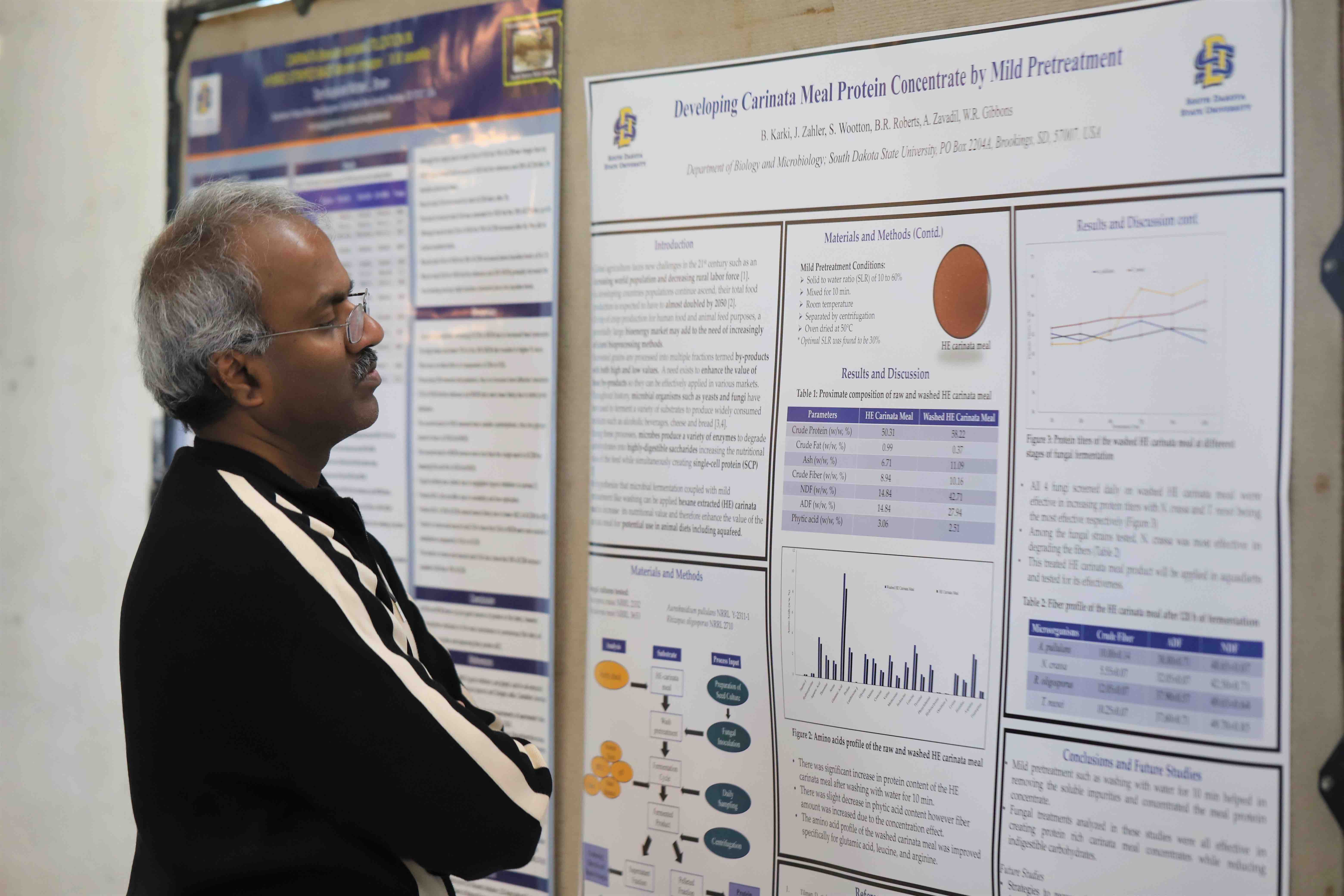

Biobased Chemicals from Carinata Seed Meal: In order for Carinata seed meal to serve as an effective feed for livestock, (1) it must have nutritional value and (2) it must be suitably palatable for the animal. It is well documented that the seed meal is protein rich (43–46%), but it contains glucosinolates, the mustardy compounds that generally repel herbivores. One of these, sinigrin, can constitute about 4–7% by weight of the meal and thus, its removal or passivation is crucial. Perhaps the second most abundant molecule in the seed meal is sinapine, another anti-nutritional (and bitter) component with variable content (reportedly up to 1.6%) in the seeds of Brassica species. Sinapine was first isolated in 1825 (Etienne Ossian Henry) from mustard seeds and is named after the Greek word for mustard (sínapi, σίναπι). It is the choline ester of sinapic acid and is a building block for lignin synthesis.

The Miller Research Group at the University of Florida has developed seed meal extraction protocols that remove sinapine and then isolate sinapic acid with over 3% crude yield, by mass. Importantly, the optimized protocols are mild and render perfectly edible seed meal. Sinapic acid is structurally related to the more naturally abundant cinnamic acid derivatives, ferulic acid and coumaric acid. All three have demonstrated anti-oxidant and anti-microbial functions. Thus, one targeted application of sinapic acid is to replace the synthetic food preservatives BHT (butylated hydroxytoluene) or BHA (butylated hydroxyanisole). Another application is for synthesizing bioplastics. The Miller Research Group has created a variety of bioaromatic polyesters from ferulic, coumaric, and sinapic acids—with the goal of mimicking the commercial polyester polyethylene terephthalate (PET, water bottle plastic). The softening temperature (glass transition) of PET is near 72 °C and variations of the aforementioned bioaromatic polyesters can be tuned for softening over a very broad temperature range: 24 to 153 °C. For example, polyethylene coumarate, polyethyelene ferulate, and polyethylene sinapate soften at 109, 113, and 118 °C, respectively. The sinapic acid analogue affords the highest value and exceeds that provided by polystyrene (PS, 95 °C), another polymer targeted for replacement.

Biobased Chemicals from Carinata: How Much?: Current production yields of the carinata crop suggest the following. A 22.7 kg bag (50 pounds) will cover 10 acres and provide 18,000 kg of seed, which can be rendered into 2000 gallons of fuel and 9,000 kg of seed meal. From 10 acres, the amount of erucic acid available is 3,400 kg and the amount of azelaic acid available is 1,600 kg; but of course, their isolation would proportionally reduce the amount of liquid fuel yield.

If all U.S. Airlines converted to ReadiJetTM fuel, then the demand would be about 18 billion gallons per year. The land required for this endeavor would be about 90 million acres or 35% of existing U.S. cropland; this is roughly the size of Montana by itself, or the size of Iowa, Illinois, and Indiana combined. This giant annual crop would provide 81 billion kg of seed meal, enough to generate 14.4 billion kg of beef, more than the 12.5 billion kg of beef consumed annually in the U.S. Alternatively, this amount of seed meal could generate 25.2 billion kg of chicken, more than the 19.2 billion kg of chicken consumed annually in the U.S. The sinapic acid available (about 270 kg per 10 acres) would be 2.4 billion kg. For perspective, this is about four times the worldwide demand for food preservatives. Thus, the leftover 1.8 billion kg of sinapic acid could put a small dent in the global plastics market, which is ~400 billion kg/year. If the erucic acid (42% of the fatty acid content) were fully removed from the seed oil before refining, then the fuel available would nearly halve. Still, 90 million acres of carinata could generate about 31 billion kg of erucic acid, which could be converted into 22 billion kg of brassylic acid. Further cannibalization of the seed oil could yield 14 billion kg of azelaic acid from the 18-carbon fatty acids (29% of the fatty acid content). The 22+14 = 36 billion kg of di-acids could put a much bigger dent in the global plastics market.

Of course, these are very ambitious numbers. In the Southeast U.S. (FL, GA, AL, SC), 5.4 million acres are in usual rotation with corn, peanuts, soybeans, and cotton. Theoretically, Carinata could be grown on these acres as a winter crop, without disrupting production of the summer crop. This scenario would provide about 1.1 billion gallons of jet fuel, 4.9 billion kg of seed meal, and 140 million kg of sinapic acid. With these amounts the United States could: fly its jets for 3 weeks; eat chicken for one month; and replace all of its synthetic food preservatives.

The Carinata Biomill: As carinata fuels garner market share, the Carinata biomill will grow accordingly, expand access to the 17 chemicals and polymers described above, and most likely yield additional biobased chemicals of commercial importance. Indeed, the tiny mustard seed from Ethiopia has much potential beyond advanced fuels.

Small Farm Participation in the SPARC Project

USDA defines a small farm producer as one that grows and sells between $1,000 and $250,000 per year in agricultural products. The majority of farms in Florida are small farms. The potential exists for small farm producers in Florida to grow carinata as a winter oilseed crop profitably if they pool their resources and efforts to grow cooperatively.

Farm cooperatives are not a new concept and have been around since the mid-1800s. They center on a common cause or need to lower cost of production, labor, equipment, and other related operating expense. If organized appropriately, a small farm carinata cooperative can be profitable, provide extra farm income in the winter, provide opportunity for infrastructure and business development related to a range of carinata products including low carbon, renewable, jet and diesel fuel, plastics and other coproducts, as well as protein feed supplements. As a starting point, the farmer cooperative should conduct an economic feasibility analysis, address major production impediments, and take stock of any other known deficiencies. A plan will be needed to tackle and resolve these concerns prior to going into production.

Perceived small farm producer barriers to carinata production:

• Harvest machinery

• Transportation to grain elevator

• Consistency of seed quality between field co-ops

• Sourcing improved carinata varieties

For the economic feasibility analysis, the farmer cooperative will need to know the target price or the break event point of production, for example, the number of acres a farmer would need to put into production to be profitable. This would also help to identify how many members the cooperative should have.

The production acreage profit margin for carinata is around 200 acres. Many small farm producers willing to grow carinata as a winter crop for seed oil and livestock feed supplement may not have that much farmland that can be put into carinata production but may be able to do so through a farm

cooperative.

As part of the SPARC Extension objective relative to documenting drivers of adoption and assessing stakeholder needs, a pilot program needs to be developed to encourage farmer coop participation with price guarantees. The pilot would help to identify and address impediments of production and related logistics of downstream activities such as transportation, storage, seed crushing, fuel production and so on. If organized appropriately, a small farm carinata cooperative can be a profitable venture, provide extra farm income, and most importantly, revitalize rural communities where cooperating farmer members live.

SPARC Member Spotlight

Benjamin Christ is a Social Science researcher and Communications expert at the University of Florida. He has had some unique experiences prior to his current status that position him well for his engagement with SPARC. Ben hails from Imperial, Missouri where he attended University of Missouri to pursue a Bachelor’s degree in Fisheries & Wildlife Science. He conducted research in avian ecology. He completed his undergraduate education in Valparaíso, Chile. He then spent some time in Brazil teaching Business English to executives in São Paulo, where he drew the connection between his interest in nature and society. That spurred him to return to the US to pursue graduate studies. At the University of Florida he got a master’s degree in Sustainable Development Practice. As part of his field practicum he chose to work in partnership with IPÊ, a Brazilian ecological research institute. There he focused on understanding factors that would encourage farmers to participate in reforestation programs in the Atlantic Forest in Southeast Brazil.

Benjamin Christ is a Social Science researcher and Communications expert at the University of Florida. He has had some unique experiences prior to his current status that position him well for his engagement with SPARC. Ben hails from Imperial, Missouri where he attended University of Missouri to pursue a Bachelor’s degree in Fisheries & Wildlife Science. He conducted research in avian ecology. He completed his undergraduate education in Valparaíso, Chile. He then spent some time in Brazil teaching Business English to executives in São Paulo, where he drew the connection between his interest in nature and society. That spurred him to return to the US to pursue graduate studies. At the University of Florida he got a master’s degree in Sustainable Development Practice. As part of his field practicum he chose to work in partnership with IPÊ, a Brazilian ecological research institute. There he focused on understanding factors that would encourage farmers to participate in reforestation programs in the Atlantic Forest in Southeast Brazil.

In SPARC he works alongside Dr. Wendy-Lin Bartels on the social science team to identify barriers and opportunities associated with farmers adopting Carinata into their existing crop rotations. His experience with facilitation and stakeholder communication enable him to employ human focused methods to understand the unique perspectives of different stakeholders. He contextualizes, compares and contrasts these perspectives to extract information that can promote sustainable Carinata commercialization in the Southeast US, which is the overall mission of SPARC.

Ben has been extremely productive in SPARC with several poster presentations, talks at meetings, and publications in the pipeline. Ben loves to cook in his spare time and is “desperately” trying to grow plants in his apartment. He has found a new passion in brewing the perfect cup of coffee to make someone’s day that also allows him to do what he finds most satisfying…engaging with people.

Dr. Ken Boote is an Adjunct Professor at the University of Florida’s Agricultural and Biological Engineering Department, and Professor Emeritus at the Agronomy Department. Prior to that he had a long stint with the Agronomy Department working on crop physiology and crop modeling. His focus especially is on photosynthesis, whole plant growth, C and N metabolism of crops in response to climate change factors. He has been a co-developer of dynamic models for several food crops such as soybean, peanut, faba bean, maize, perennial forages and so on. His models can be used to enhance physiological understanding, improve crop management strategies and evaluate physiological traits or genetic improvement.

Dr. Ken Boote is an Adjunct Professor at the University of Florida’s Agricultural and Biological Engineering Department, and Professor Emeritus at the Agronomy Department. Prior to that he had a long stint with the Agronomy Department working on crop physiology and crop modeling. His focus especially is on photosynthesis, whole plant growth, C and N metabolism of crops in response to climate change factors. He has been a co-developer of dynamic models for several food crops such as soybean, peanut, faba bean, maize, perennial forages and so on. His models can be used to enhance physiological understanding, improve crop management strategies and evaluate physiological traits or genetic improvement.

In SPARC he brings his crop physiology expertise to develop similar models for Carinata, especially adapting the CROPGRO model for Carinata. There being sparse literature on Carinata Dr. Boote’s modeling efforts will go a long way to establish scientific literature on Carinata growth and development, and inform future breeding strategies for enhanced yield and productivity for sustainable commercialization of Carinata in the Southeast US.

Dr. Boote spends a lot of time in passing on his skills to the next generation both within and outside the country. He is involved in USAID projects working in developing nations for crop improvement of significant food crops. He has served as a consultant for the Global Futures Project of the International Food Policy Research Institute. He was coordinator of the Crop Modeling for Agricultural Model Improvement and Inter-comparison project to advise scientists on the use of crop models in response to climate change factors. He has assisted with capacity building and assessment of climate impact on crop production in sub Saharan African and South Asian countries.

Dr. Boote continues to stay highly productive on national and international funded projects. During his career he has received several honors and awards including Fellow of the Agronomy Society of America, Crop Science Society of America and AAAS. He has numerous well cited publications to his credit.

Dr. Boote grew up on a farm in Iowa and wanted to be an extension agronomist before deciding on a career in scientific discovery. He loves learning about new things and making pieces of the puzzle all fit together. He continues to travel far and wide as part of his various commitments, all with the goal of applying the science of crop modeling to meet global food and energy needs

Dr. Carl Crozier is Professor at North Carolina State University in the Department of Crop and Soil Sciences. He is a Cooperative Extension Specialist dealing with soil fertility management for the Tidewater region of North Carolina including nitrogen management for corn and wheat, precision agriculture for agronomic crops and biofuel oilseed and grass production.

Dr. Carl Crozier is Professor at North Carolina State University in the Department of Crop and Soil Sciences. He is a Cooperative Extension Specialist dealing with soil fertility management for the Tidewater region of North Carolina including nitrogen management for corn and wheat, precision agriculture for agronomic crops and biofuel oilseed and grass production.

Dr. Crozier has a PhD in Soil Science, a Master’s degree in Botany from the Ohio State University and a Bachelor’s degree in Biology from Baylor University. His interest in agricultural systems comes from working on his family ranch in Gonzales Co. TX and his stint with the US Peace Corps that took him to Honduras.

In SPARC, as part of the Carinata best management practices team, Carl brings his expertise in soil fertility to fine tune Carinata nutrient management and tailor it for sustainable Carinata production in different regions in the Southeast US. What he especially finds rewarding is the training he is able to provide extension agents and farmers, and the communication he is able enhance among researchers, the production agriculture sector, and the general public in the design of more efficient research and extension programs.

Carl and his botanist wife Teresa have 3 children, who also are following in their parent’s footsteps pursing degrees in geology, crop science, and marine science. They spend a lot of time outdoors as a family, hiking, bicycling and kayaking. Carl is an avid nature photographer using plant photos as a way to learn native plant identification. He also tries to contribute toward his family ranch as a long-distance partner because that’s where it all began.

SPARC Graduate Spotlight

Tessa Schulmeister is a PhD student in the Animal Science Department at the University of Florida under the guidance of Dr. Nicolas DiLorenzo. Prior to that she received a Master’s Degree from the same deprtmanert and a BS in Biology from Northern Illinois University. She got involved in livestock relate research at during her undergraduate education where she was involved in research looking a thte effects of bedding on non-stinging parasitoid wasps which have potential as biological control of pest-flies in areas of livestock production.

Tessa Schulmeister is a PhD student in the Animal Science Department at the University of Florida under the guidance of Dr. Nicolas DiLorenzo. Prior to that she received a Master’s Degree from the same deprtmanert and a BS in Biology from Northern Illinois University. She got involved in livestock relate research at during her undergraduate education where she was involved in research looking a thte effects of bedding on non-stinging parasitoid wasps which have potential as biological control of pest-flies in areas of livestock production.

Tessa has been actively involved in carinata even before SPARC and continues to explore carinata meal as an alternative protein source for beef cattle in the Southeast US. She has already evaluated the meal as far as animal performance is concerned. Her future research will include understanding the effect of carinata meal on animal reproduction and fetal programming, carcass characteristic of carinata fed cattle during finishing, effects on increasing carinata inclusion levels in cattle diet and the potential of carinata to mitigate methane emissions in beef cattle consuming forage based diets.

Tessa is originally from Dothan, Alabama where she grew up surrounded by agriculture but not actively involved in it. Tessa was enlisted in the Navy as an Aviation Ordnanceman, received honorable discharge from the Navy, after which she pursued her career in science.

Tessa recently won first place at the SPARC Annual Student Oral Competition for her presentation on the relationship between her research on carinata meal for beef cattle and the overall SPARC mission of commercializing carinata in the Southeast US. Tessa enjoys spending time with her children, cooking and reading.

Jacenta Hinton is a SPARC graduate student pursuing her Master’s Degree in Agronomy at the Florida Agricultural & Mechanical University under the guidance of Dr. Oghenekome Onokpise. Prior to starting her Master’s degree Jacenta completed a bachelor’s degree in Chemistry from Alcorn State University in Lorman, MS. Her interest in pursuing a higher degree in agronomy came from her having a science degree with a focus on biochemistry followed by an internship she did at the USDA-ARS.

Jacenta Hinton is a SPARC graduate student pursuing her Master’s Degree in Agronomy at the Florida Agricultural & Mechanical University under the guidance of Dr. Oghenekome Onokpise. Prior to starting her Master’s degree Jacenta completed a bachelor’s degree in Chemistry from Alcorn State University in Lorman, MS. Her interest in pursuing a higher degree in agronomy came from her having a science degree with a focus on biochemistry followed by an internship she did at the USDA-ARS.

In SPARC Jacenta is looking at best management practices for carinata, especially row spacing studies to optimize carinata yield, seed quality, oil yield and oil quality. Being a student at the 1890 HBCU institution she is also actively engaged with limited resource farmers. She participates in field days and workshops specifically geared toward these stakeholders to understand limitations and opportunities with carinata, in their context.

Jacenta loves to surf the web in her spare time, mostly watching self-grooming tutorials, and spend time with family and friends. She enjoys traveling back to South Mississippi where she is from, to eat her favorite seafood. She is a history buff and loves to go to different museums to expand her knowledge in US and world History.

Omid Karami is a second-year doctoral student at the University of Georgia’s Warnell School of Forestry and Natural Resources under the guidance of Dr. Puneet Dwivedi. Omid hails from Isfahan province of Iran. He completed his undergraduate education at Tabriz University (2010), and obtained a Master’s degree at Tehran University (2013) in agricultural economics. During his masters he explored the impact of agriculture on the environment and non-market valuation of environmental services. He worked as a research assistant at Tehran University between 2014 and 2016 before joining University of Georgia in 2017 for his doctoral studies.

In SPARC, Omid is analyzing optimum crop rotations that can include carinata in South Georgia with a strong focus on market and climate risks. He works collaboratively across disciplines with the feedstock development, fuel and coproduct development and supply chain teams in order to get comprehensive data to feed into his models.

In his spare time, Omid plays soccer and watches political/economical documentaries. His hobbies include cooking and doing sheet metal embossing.

Upcoming Events

April 30, 2019 – Florida A&M University Cooperative Extension will organize the Alternative Crop Enterprise Workshop featuring Carinata. Drs. Seepaul, Wright, Bolques and Onokpise of SPARC will speak during this workshop For details go to www.sparc-cap.org.

May 20, 2019 – UF/IFAS Extension will organize the Prospective Alternative Crops of North Florida program including a field tours of carinata at the North Florida Research & Education Center, Suwanee Valley (program starts at 5:30 PM EDT). De Broughton and Dr. Ian Small of SPARC will lead the sessions on carinata.

May 27-30, 2019 – An abstract submitted to the European Biomass Conference & Exhibition by Drs. Dan Geller and George Philippidis was accepted. Dr. Philippidis will deliver the talk at the meeting which will be held in Lisbon,Portugal.